The team presenting at our poster night

PMDP is non-profit organization that removes ghost nets (fishing nets that have been dumped into the ocean) from the Papahanaumokuakea Marine Nation Monument (PMNM). In a two-quarter long project, my team worked with them to figure out a new material stream for the thousands of tons of nets that PMDP was pulling out of the ocean, the majority of which was being burned for energy. We had a remarkable degree of freedom in this project, as PDMP didn't have a specific direction they wanted us to take. We connected with their partner, the Center for Marine Debris Research (CMDR), to help with their research, which is currently to determine the strength of recycled plastic that could be made from the retrieved nets, and what it could be used for. You can learn more about PMDP or CMDR and their work by clicking below.

Our first step was to research what ghost nets were, what materials they tended to be made of, and what was currently happening with them. As we didn't have a specific project to start, we needed a good idea of what was out there and what was missing, in case we could fill any gaps. This meant reading a ton of research papers about ghost net plastics and their properties and meeting with many other organizations doing similar research to recycle discarded fishing nets. Recycling recovered nets is tricky, because they are often degraded by sun or sand or have marine growth on them. The washing process of these plastics is time consuming and expensive (in both materials and money), and still produces lower quality plastic than just making it new.

With all of our information gathered, and a bit of discussion with CMDR, we settled on helping them test the properties of recycled plastic made from shredded net material. They have a hypothesis that some amount of coral growth could replace the current additives used in manfacturing plastic, which would significantly decrease the difficulty of washing and recycling biofouled plastics. As Stanford students (and with the Materials Science connections of one of our teammates), we had access to some expensive specialized testing equipment that could supplement CMDR's research. In order to be able to test the nets, we needed to make shred them, then compress or extrude the shreds into the testing shape (called a dog bone), then load them into the tester. We would test the process on nets from another class's project while CMDR sorted and sent us samples of their nets.

With all of our information gathered, and a bit of discussion with CMDR, we settled on helping them test the properties of recycled plastic made from shredded net material. They have a hypothesis that some amount of coral growth could replace the current additives used in manfacturing plastic, which would significantly decrease the difficulty of washing and recycling biofouled plastics. As Stanford students (and with the Materials Science connections of one of our teammates), we had access to some expensive specialized testing equipment that could supplement CMDR's research. In order to be able to test the nets, we needed to make shred them, then compress or extrude the shreds into the testing shape (called a dog bone), then load them into the tester. We would test the process on nets from another class's project while CMDR sorted and sent us samples of their nets.

There were two ways we could melt the shreds to create the dog bones. The first would be to extrude them from a machine that would melt, compress, and mix the plastic, then push it out into either a sheet or (ideally) our preferred shape. Unfortunately, the extruders we had access to were either nonfunctional or we were unable to use recycled material in them. Our second option was to use pressure and heat to take the scaps and melt them together into either a sheet or our preferred shape. We had access to a heat press, and determined that would work best. Ideally, we could make a mold, determine how much shred would fill the mold, add our measured and shredded nets, and compress it nicely into the mold.

There were two ways we could melt the shreds to create the dog bones. The first would be to extrude them from a machine that would melt, compress, and mix the plastic, then push it out into either a sheet or (ideally) our preferred shape. Unfortunately, the extruders we had access to were either nonfunctional or we were unable to use recycled material in them. Our second option was to use pressure and heat to take the scaps and melt them together into either a sheet or our preferred shape. We had access to a heat press, and determined that would work best. Ideally, we could make a mold, determine how much shred would fill the mold, add our measured and shredded nets, and compress it nicely into the mold.

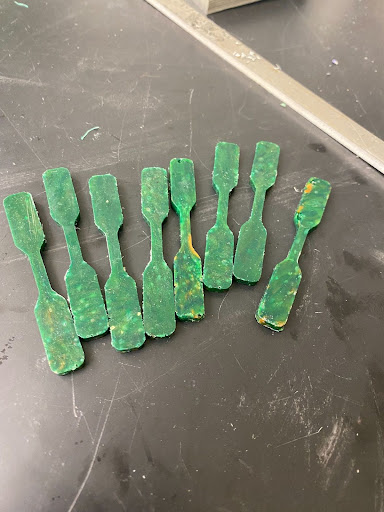

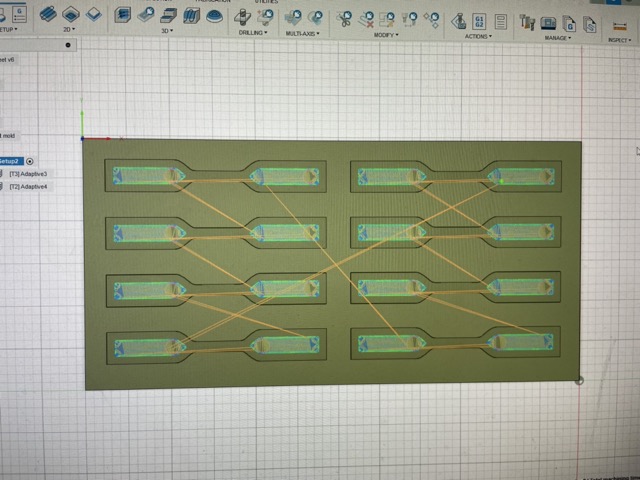

We decided that it would be best to make molds in the shape of the dog bones we needed, as that would be a more precise and repeatable method than creating sheets. As the most manufacturing-inclined of our team, I modeled and machined the molds. They were made on a HAAS CNC mill, first as a single bone, then as a set of eight on one mold. The samples that we needed for the type of plastic were quite small, so having so many on one mold would make each use of the heat press much more efficient. In order to remove the bones and for excess material to escape the mold, I used a manual mill to create sprues for each cavity. Once the silgle mold was made and tested, we were ready to produce our dog bones.

We decided that it would be best to make molds in the shape of the dog bones we needed, as that would be a more precise and repeatable method than creating sheets. As the most manufacturing-inclined of our team, I modeled and machined the molds. They were made on a HAAS CNC mill, first as a single bone, then as a set of eight on one mold. The samples that we needed for the type of plastic were quite small, so having so many on one mold would make each use of the heat press much more efficient. In order to remove the bones and for excess material to escape the mold, I used a manual mill to create sprues for each cavity. Once the silgle mold was made and tested, we were ready to produce our dog bones.

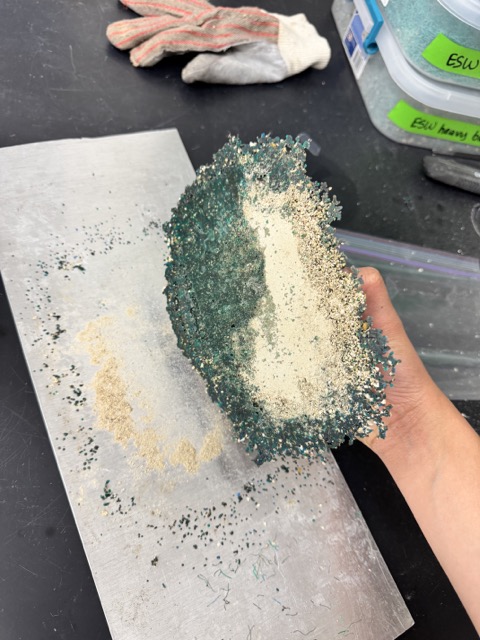

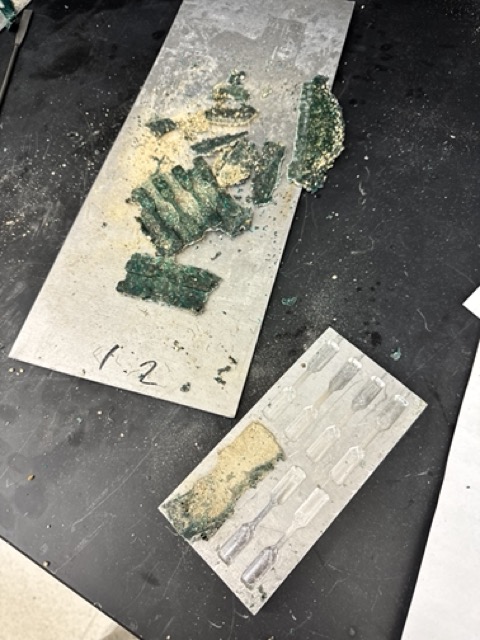

We had four different levels of biofouling that we were attempting to test: none, light, medium, and heavy. After spraying the mold with mold release, our process for using the mold in the heat press went as follows: heat the press, premelt some of the shreds on the bottom plate of the mold, add shreds in exess of what fits into the mold, place the mold facedown on the net shreds, compress the heat press until the pressure stabilizes. When the mold was fully compressed, we let it melt for about ten minutes, then left it to cool for a couple hours. Once it was cool, we removed the bones and started the next batch.

We had four different levels of biofouling that we were attempting to test: none, light, medium, and heavy. After spraying the mold with mold release, our process for using the mold in the heat press went as follows: heat the press, premelt some of the shreds on the bottom plate of the mold, add shreds in exess of what fits into the mold, place the mold facedown on the net shreds, compress the heat press until the pressure stabilizes. When the mold was fully compressed, we let it melt for about ten minutes, then left it to cool for a couple hours. Once it was cool, we removed the bones and started the next batch.

We tested the dogbones on an MTS Criterion 43 in one of the engineering labs. At the most basic level, testing is done by clamping each dogbone into the grips, measuring the distance between grips, and starting the machine with standardized settings. Once the machine detects a break, it stops pulling the grips apart, and gives us the data it measured while pulling. Due to time constraints we weren't able to make as many of each sample as we wanted For more information about the exct process and setting we used, you can check our paper, which is linked at the bottom of this page.

We tested the dogbones on an MTS Criterion 43 in one of the engineering labs. At the most basic level, testing is done by clamping each dogbone into the grips, measuring the distance between grips, and starting the machine with standardized settings. Once the machine detects a break, it stops pulling the grips apart, and gives us the data it measured while pulling. Due to time constraints we weren't able to make as many of each sample as we wanted For more information about the exct process and setting we used, you can check our paper, which is linked at the bottom of this page.

Due to time constraints we weren't able to make as many of each sample as we wanted, but we were able to recognize a pattern anyway. Despite our hypothesis (and hope) that there was a level of biofouling that would increase the strength of the plastic, we found that each level of biofouling was correlated with a decrease in tensile strength at break. However, our mold process had some difficulties, especially with higher levels of biofouling, so that many have influenced the quality of our dogbones. Due to time constraints we were also unable to make as many samples as we would have preferred, which likely effected the severity of the results. More testing will have to be done on the subject to verify our results.

A selection of photos from the duration of this project

The team presenting at our poster night

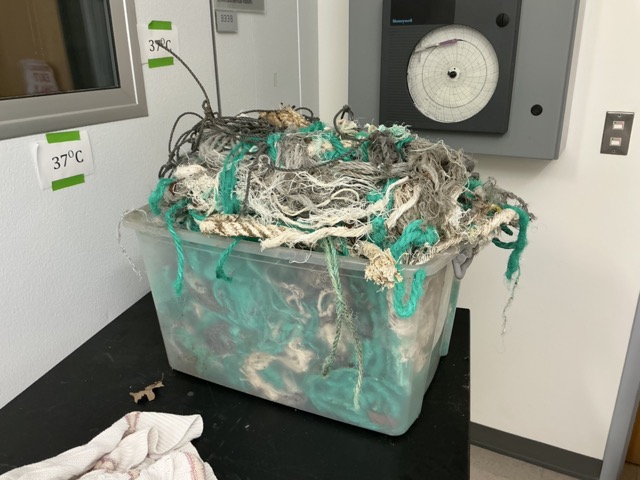

Nets for experimenting with the mold

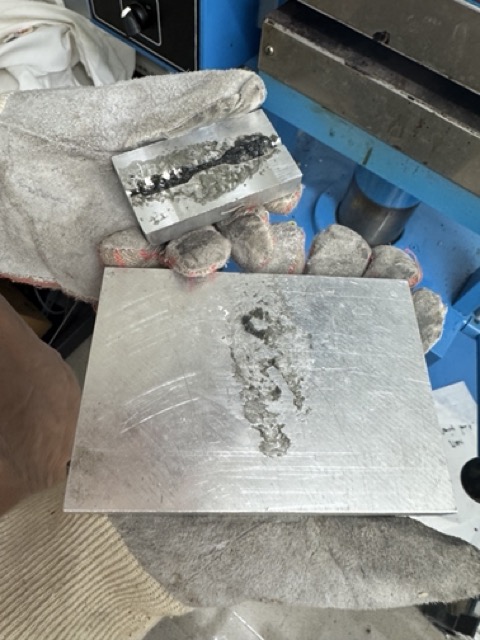

Attempt at melting net shreds

Single mold after machining

First attempt at using the mold

First attempt at top down mold use

CAM pathing for the 8 bone mold

Big mold after machining

Unpacking samples from CMDR

Clean samples in the mold

Clean samples, removed and labeled

Medium biofoul samples, mostly removed

Heavy biofoul samples in the mold

Attempt to remove heavy biofoul samples

Tensile testing of our samples